SCIENCE

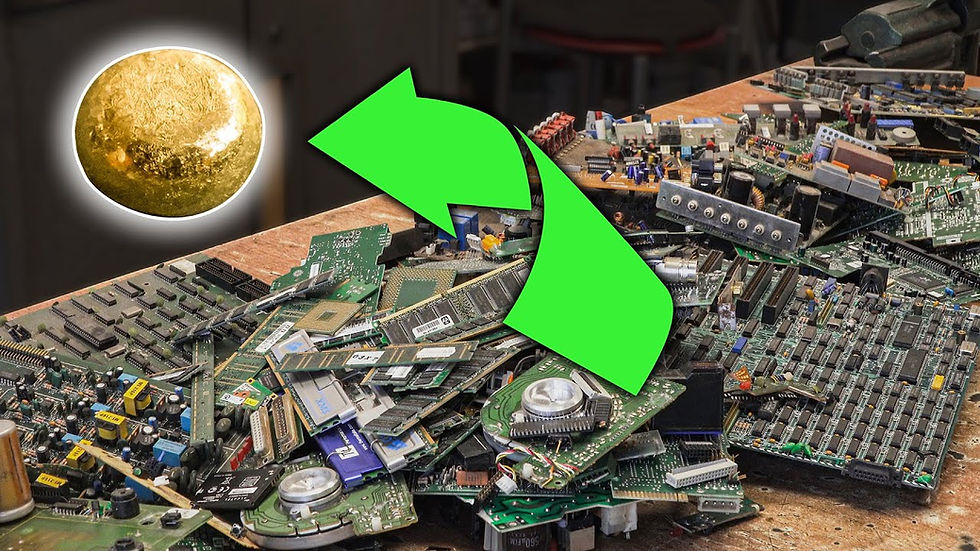

A Cornell University-led research team has developed a method for extracting gold from electronics waste. About 50 million tons of e-waste are discarded each year, only 20% of which is recycled, says Amin Zadehnazari, a postdoctoral researcher in the lab of Alireza Abbaspourrad, professor of food chemistry and ingredient technology. Zadehnazari has developed a way to remove gold ions and nanoparticles from circuit boards in discarded electronic devices and capture a record 99.9% of the gold and very little of other metals, including nickel and copper.

E-waste is a literal gold mine: It’s estimated that a ton of e-waste contains at least 10 times more gold than a ton of the ore from which gold is extracted. And with an anticipated 80 million metric tons of e-waste by 2030, it’s increasingly important to find ways to recover the precious metal.

Traditional methods for recovering gold from e-waste involve harsh chemicals, including cyanide, which pose environmental risks. Zadehnazari’s method is achieved without hazardous chemicals, using chemical adsorption — the adhesion of particles to a surface.

Abbaspourrad is corresponding author and Zadehnazari lead author of Recycling E-waste Into Gold-loaded Covalent Organic Framework Catalysts for Terminal Alkyne Carboxylation, which has been published in Nature Communications.

MEANWHILE

Wearable e-textiles get greener

A research team in Britain has come up with wearable electronic textiles (e-textiles) that are both sustainable and biodegradable. The fabric is fully inkjet-printed, and they’re calling it Smart, Wearable, and Eco-friendly Electronic Textiles, or SWEET, for short.

The team was led by the University of Southampton and UWE Bristol together with the universities of Exeter, Cambridge, Leeds and Bath.

E-textiles have embedded electrical components, such as sensors, batteries or lights and might be used in fashion, for performance sportswear, or for medical purposes as garments that monitor people’s vital signs. Such textiles need to be durable, safe to wear and comfortable, but also in an industry increasingly concerned with clothing waste, they need to be kind to the environment when no longer required.

Professor Nazmul Karim at the University of Southampton’s Winchester School of Art, who led the study, explains, “Integrating electrical components into conventional textiles complicates the recycling of the material because it often contains metals, such as silver, that don’t easily biodegrade. Our potential eco-friendly approach for selecting sustainable materials and manufacturing overcomes this, enabling the fabric to decompose when it is disposed of.”

The team’s design has three layers: a sensing layer, a layer to interface with the sensors and a base fabric. It uses a textile called Tencel as the base, which is made from renewable wood and is biodegradable. The active electronics in the design are made from graphene, along with a polymer called PEDOT: PSS. These conductive materials are precision inkjet-printed onto the fabric.

The researchers tested samples of the material for continuous monitoring of human physiology using five volunteers. Swatches of the fabric, connected to monitoring equipment, were attached to gloves worn by the volunteers. Results confirmed the material can effectively and reliably measure both heart rate and temperature at the industry-standard level. (Heart-related diseases affect 640 million people worldwide.)

Dr Shaila Afroj, Associate Professor of Sustainable Materials at the University of Exeter and a co-author of the study, says, “Achieving reliable, industry-standard monitoring with eco-friendly materials is a significant milestone. It demonstrates that sustainability doesn’t have to come at the cost of functionality, especially in critical applications like healthcare.”

The project team then buried the e-textiles in soil to measure its biodegradability. After four months, the fabric had lost 48% of its weight and 98% of its strength, suggesting relatively rapid and also effective decomposition. Furthermore, a lifecycle assessment revealed the graphene-based electrodes had up to 40 times less impact on the environment than standard electrodes. Marzia Dulal from UWE Bristol and first author of the study says, “Our lifecycle analysis shows that graphene-based e-textiles have a fraction of the environmental footprint compared to traditional electronics. This makes them a more responsible choice for industries looking to reduce their ecological impact.”

The inkjet printing process is also a better approach for e-textile fabrications, depositing exact numbers of functional materials on textiles as needed, with almost no material waste and less use of water and energy than conventional screen printing.

Professor Karim concludes, “Amid rising pollution from landfill sites, our study helps address a lack of research in the area of biodegradation of e-textiles. These materials will become increasingly more important in our lives, particularly in the area of healthcare, so it’s really important we consider how to make them more eco-friendly, both in their manufacturing and disposal.”

Comments